无锡总公司

地址:无锡惠山区智慧路33号56栋

电话:0510-83762181

邮箱:sales@topnst.com

深圳分公司

地址:深圳市龙华区观澜街道桂月路310号知寓桂园电子商务大厦218室

法律声明

Copyright © 2020 - 江苏诺森特电子科技有限公司- All rights reserved.

备案号:苏ICP备14054729号

技术支持:千客云营销

微信公众号

微信公众号

诺森特TOP系类的脉冲热压焊接机多年来被广泛的应用于电子机器和电子零件的焊锡焊接,树脂热熔,热压接等领域,并受到一致好评。

近年来以手机为代表的电子终端机器的功能和性能的进化迅速发展,在电子元器件的小型化,高性能化发展的同时,零件高密度组装技术变得尤为重要,要求其中零件制造和组装的关键技术焊锡焊接对应更加小型化和具有高可靠性,

我司随着技术可信在日新月异的制造业中,迅速对应客户的要求并提供最佳的焊接解决方案。

NouSenTe TOP series pulse thermocompression welding machines have been widely used in the fields of solder welding, resin hot melting and thermocompression bonding of electronic machines and electronic parts for many years, and have been well received.In recent years, the evolution of the function and performance of electronic terminal machines represented by mobile phones has developed rapidly. With the development of miniaturization and high performance of electronic components, the high-density assembly technology of parts has become particularly important, which requires the key technology of parts manufacturing and assembly, solder welding, to be more miniaturized and reliable.With the reliable technology, our company quickly responds to customers' requirements and provides the best welding solutions in the ever-changing manufacturing industry.

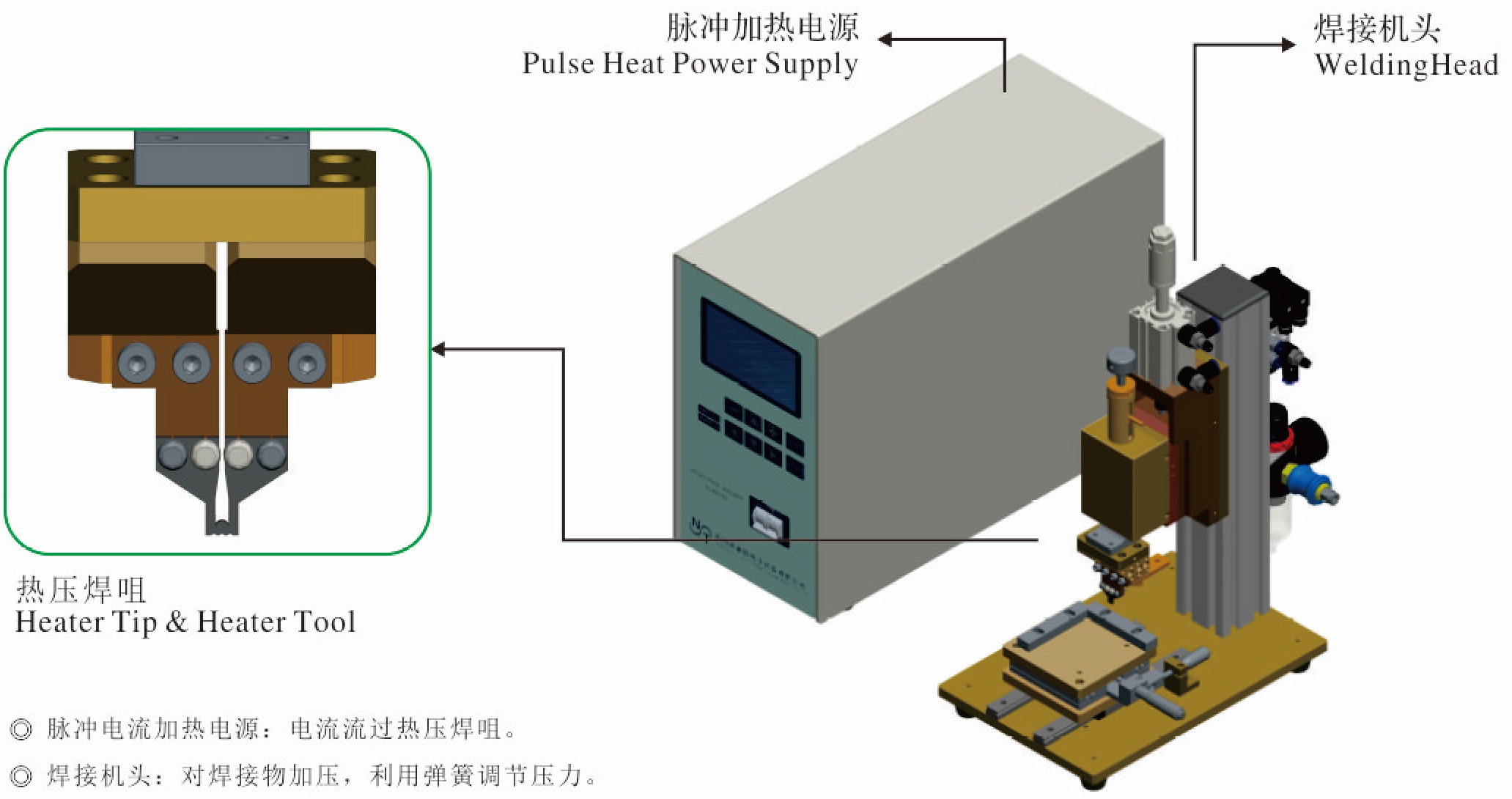

▲脉冲热压焊接是对电子零部件进行焊锡或对树脂零部件进行热熔接的机器,由施加压力的焊头和控制脉冲电流的电源组成。

▲脉冲热压焊接机是只在融化焊锡或者树脂时瞬间通电的加热方式;

▲金属制的焊咀有电流通过时产生焦耳热而融化焊锡或者树脂,融化后停止通电进行冷却。

▲在加压状态下直到焊锡凝固为止,可以得到高信赖兴的没有虚焊,浮起的焊接。

▲Pulse hot pressing welding is a machine for soldering electronic parts or hot welding resin parts, which consists of a welding head for applying pressure and a power supply for controlling pulse current.

▲ The pulse hot-pressing welding machine is a heating method that is only energized instantly when melting solder or resin。

▲ When current flows through the metal nozzle, Joule heat is generated to melt the solder or resin, and after melting, the power supply is stopped for cooling.

▲ In the pressurized state until the solder solidifies, you can get high-reliability welding without virtual welding and floating.

▲节能降耗:焊接时通电加热熔化焊锡或者树脂,荣哈后断电冷却,待机能耗低。

▲高可靠性:在加压的状态下直到焊锡凝固,可以得到高信赖得没有虚焊,浮起的焊接。

▲高速精准:设备焊接稳定可靠,避免需要熟练的焊锡人工,以及焊锡对人员的健康影响问题。

▲降低锡本:只需要合适的锡量就可以保证可靠的焊接,避免人工浪费锡丝

▲高智能性:针对特殊产品及高智能自动化产品或者人工无法焊接,Hotbar可以有效的自动化高智能生产。

▲一致性强:Hotbar焊接机有效的取代人工的不规律性,可以保证产品焊接的外观及焊点的一致性,

▲ Energy saving and consumption reduction: during welding, power on heating to melt solder or resin, power off cooling after Rongha, and standby energy consumption is low.

▲ High reliability: Under pressure until the solder solidifies, it can obtain highly reliable welding without false soldering or floating.

▲ High speed and precision: The equipment welding is stable and reliable, avoiding the need for skilled soldering labor and the health impact of soldering on personnel.

▲ Reduce tin cost: Only a suitable amount of tin is needed to ensure reliable welding and avoid manual waste of tin wire

▲ High intelligence: Hotbar can effectively automate high intelligence production for special products, highly intelligent automated products, or those that cannot be welded manually.

▲ Strong consistency: Hotbar welding machines effectively replace manual irregularity, ensuring the consistency of product welding appearance and solder joints,

❂ 诺森特TOP脉冲热压焊接机构成与作用

Composition and function of NouSenTe TOP pulse hot press welding machine

对焊接工件加压的同时,通电,利用产品的焦耳热进行焊接的方式 、

By applying pressure to the welded workpiece while applying electricity and utilizing the Joule heat of the product for welding

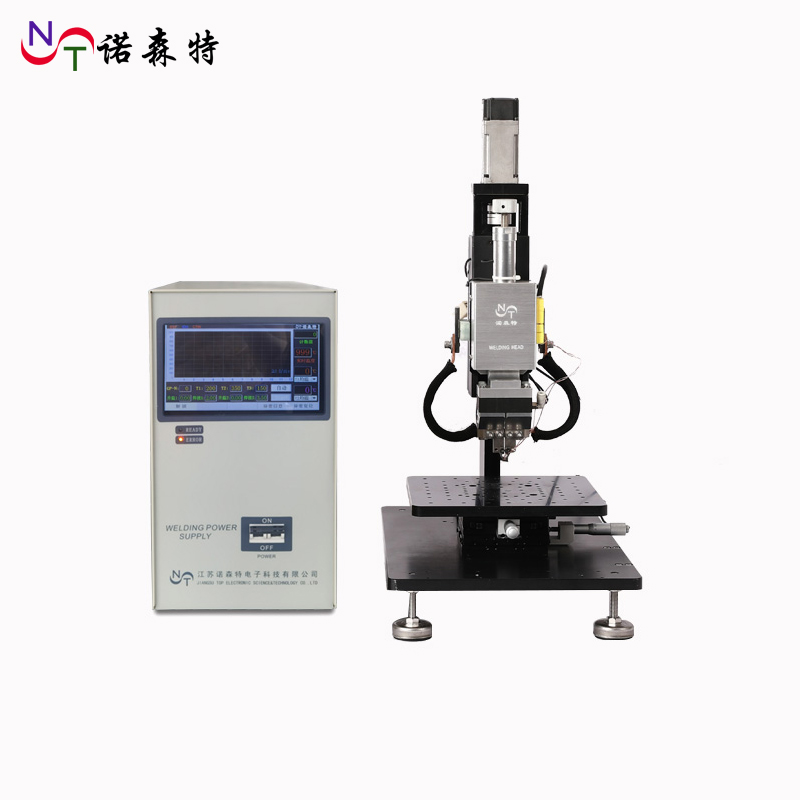

❂ 诺森特TOP脉冲热压焊接机展示

Northrend TOP pulse hot press welding machine display

其他非标定制款 脉冲热压焊锡机 ↓

王工

蔡工